Walter Clayton Jr Daughter - A Legacy Of Industrial Excellence

Exploring the lasting impact of a name often brings us to unexpected places, and in the case of "Walter Clayton Jr daughter," we find ourselves looking at a story of enduring quality and forward-thinking solutions within the industrial tools world. It's almost as if the very spirit of progress, that desire to help things work better, is passed down, much like a family's cherished values. This deep commitment to helping industries achieve their very best, you know, really shines through in the way certain companies operate, embodying a dedication that feels very personal.

When we think about the contributions that shape an industry, it's not always about a single person, but often about the collective vision and the practical steps taken to bring that vision to life. The phrase "Walter Clayton Jr daughter" might make one consider a direct lineage, yet, it also brings to mind the continuation of a particular philosophy, a way of approaching challenges with an eye toward innovation and genuine help. It’s about building something that stands the test of time, something that provides real, tangible benefits to those who use it every single day.

This idea of a lasting legacy, or perhaps, a "daughter" of a foundational vision, can be clearly seen in the operations of Walter Surface Technologies. This is a company that, in some respects, seems to carry forward a tradition of supplying expert solutions, making sure the metalworking industry, and others like it, can truly achieve greatness. They focus on delivering products that are not just new, but also safe and sustainable, helping people work better, which, you know, is a pretty significant thing in today's demanding work environments. It's all about providing the right tools and services, making a real difference where it counts.

- Polarizado Nanoceramica Vs Normal

- Beauty In Black True Story

- Cade Cunningham Daughter Mom

- Natalia Grace Barnett Net Worth

- Did Khloe Kardashian Son Pass Away

Table of Contents

- The Enduring Story of Walter Surface Technologies

- What Makes Walter Surface Technologies a True Partner for the Metalworking Community?

- Unpacking the Expert Solutions for Industrial Work

- How Do Walter Surface Technologies' Abrasives Stand Out?

- Ensuring Safety and Consistency on the Job

- Why is Tool Identification a Big Deal in the Shop?

- A Closer Look at Annular Cutters

- What Future Innovations Might the Walter Clayton Jr Daughter Line Bring?

The Enduring Story of Walter Surface Technologies

When we talk about the "biography" of a company like Walter Surface Technologies, it's less about a single person's birthdate and more about the journey of an idea, a commitment to quality that, you know, has grown over time. This story is very much about how a business grows to provide expert solutions for industrial tools, abrasives, and the kinds of services that truly support a demanding industry. It's a tale of constant refinement, always looking for better ways to do things, which is quite admirable.

The core of this company's story is its dedication to helping the metalworking industry, making sure it can achieve what they call "greatness." This isn't just about selling things; it's about being a true partner, offering the solutions that help businesses thrive. So, in a way, the "biography" here is a narrative of innovation, of providing products that are not just effective, but also safe for the people using them and gentle on the planet. That's a pretty comprehensive approach, wouldn't you say?

This enduring story of Walter Surface Technologies, you know, is built on a foundation of trust and consistent performance. It’s about developing products that people can rely on, day in and day out, to get the job done right. They've put in the work to create tools and services that meet the real-world needs of industrial settings, which, in fact, is a testament to their deep understanding of the challenges faced by their customers. It's a continuous process of improvement and support.

- Its My Birthday Cash App Me

- Madelyn Cline Jean Shorts

- Sam Hartman Memes

- Torta De Gelatina

- How Long Is Okra Water Good For In The Fridge

While we might consider the personal details of a "Walter Clayton Jr daughter" in a traditional sense, when speaking of a company's journey, we look at its defining characteristics and contributions. Here are some of the key attributes of Walter Surface Technologies, reflecting its operational identity:

| Core Focus | Industrial Tools, Abrasives, and Services |

| Primary Aim | Supplying solutions for the metalworking industry to achieve greatness |

| Product Philosophy | Innovative, safe, and sustainable offerings |

| Key Product Traits | Engineered for durability and efficiency |

| Performance Standard | Safest and most consistent results on the job |

| User Convenience | Color-coded products for easy identification |

| Specialized Offerings | Annular cutters (high speed steel, cobalt, carbide tipped) up to 4” diameter and 4” depth |

What Makes Walter Surface Technologies a True Partner for the Metalworking Community?

You know, being a true partner in any industry goes beyond just selling products; it’s about understanding the specific needs and challenges that people face every single day. For the metalworking community, this means having access to tools and services that are not just good, but really, really good at what they do. It’s about providing solutions that genuinely help improve processes, make tasks easier, and ultimately, contribute to a better outcome for the work being performed. This approach, you know, is what sets some companies apart from the rest.

Walter Surface Technologies, apparently, takes this idea of partnership very seriously. They focus on supplying solutions that are designed to help the metalworking industry achieve what they call "greatness." This isn't some vague aspiration; it’s a practical commitment to providing the right equipment and support so that businesses can truly excel. They offer a range of products that are meant to make a tangible difference in how work gets done, which, in a way, supports the very backbone of industrial operations. It's about empowering people with better ways to work.

Supplying Solutions for the Walter Clayton Jr Daughter Generation

When we think about the future, about the "Walter Clayton Jr daughter generation," we're really talking about ensuring that the next wave of industrial workers and businesses have the best possible resources at their disposal. This means providing solutions that are not only effective now but are also forward-thinking, ready for whatever challenges come next. It's about equipping people with the tools that allow for continued progress and sustained success, which is a pretty significant responsibility, if you ask me.

The solutions provided by Walter Surface Technologies are designed with this kind of long-term vision in mind. They deliver innovative products, but also make sure they are safe and sustainable, helping people work better in ways that protect both the individual and the environment. This commitment to safety and sustainability, you know, reflects a deep care for the well-being of future generations, making sure that the industrial landscape remains productive and responsible. It’s a holistic approach to supporting the metalworking community for years to come.

Unpacking the Expert Solutions for Industrial Work

When we talk about "expert solutions" for industrial work, it really means going beyond the basic tools and offering something that genuinely makes a difference in a demanding environment. It’s about providing equipment and services that are backed by a deep knowledge of the industry, understanding the nuances of different materials and processes. This isn't just about selling a product; it’s about offering a complete answer to a specific challenge, making sure that every piece of the puzzle fits just right. It's quite a comprehensive approach, actually.

Walter Surface Technologies, it seems, has built its reputation on this very idea. They provide expert solutions for a wide range of industrial needs, including tools, abrasives, and various services that support the entire metalworking process. This means they've put in the effort to truly understand what their customers require, and then they've developed products that meet those requirements with precision and reliability. It’s about giving people the confidence that their tools will perform exactly as expected, every single time, which is very important in industrial settings.

How Walter Clayton Jr Daughter's Vision Shapes Tool Offerings

If we consider the idea of a "Walter Clayton Jr daughter" as a symbol of a guiding vision, then this vision undoubtedly plays a part in how Walter Surface Technologies shapes its tool offerings. It suggests a commitment to excellence that is passed down, influencing the creation of products that are not just functional but also embody a higher standard. This kind of vision would push for tools that are truly innovative, helping users achieve better results with greater ease and safety, which is a pretty good goal, wouldn't you say?

This guiding philosophy, perhaps akin to a "daughter's" inheritance of values, would emphasize the importance of continuous improvement and responsiveness to the needs of the industry. It means exploring new products today, always looking for what’s next, what can make a real difference. The tools offered are a direct reflection of this forward-thinking approach, ensuring that they are not only effective but also contribute to a safer and more sustainable working environment. It's about building a future, one tool at a time.

How Do Walter Surface Technologies' Abrasives Stand Out?

When you're working with abrasives in an industrial setting, you know, it's not just about grinding things down; it's about achieving specific finishes, removing unwanted materials, and doing it all efficiently. So, what makes one abrasive different from another? It often comes down to how well it performs under pressure, how long it lasts, and how consistently it delivers the desired outcome. These factors are pretty important for anyone working in the metalworking trade, as a matter of fact.

Walter Surface Technologies, apparently, pays a lot of attention to these details. Their abrasives are engineered specifically for durability and efficiency, which means they are designed to last longer and get the job done faster. This isn't just a claim; it’s a result of careful design and manufacturing processes that focus on the real-world demands of industrial applications. They aim to provide tools that people can rely on, reducing downtime and improving productivity, which, you know, is a significant benefit for any business.

The Walter Clayton Jr Daughter Approach to Abrasive Durability

Thinking about the "Walter Clayton Jr daughter" approach to abrasive durability brings to mind a commitment to long-lasting quality and reliable performance. It suggests a philosophy where products are built to endure, to stand up to the rigors of heavy use, rather than needing frequent replacement. This focus on durability means that the abrasives are designed to maintain their effectiveness over a longer period, providing consistent results and, in a way, a better return on investment for the user, which is pretty smart.

This emphasis on durability and efficiency is evident in the design of their abrasive products. They are made to perform consistently, whether it’s for removing paint, rust, or corrosion, or for lighter applications. This careful engineering ensures that the abrasives not only work well but also last, contributing to a smoother and more productive workflow. It’s about providing tools that people can trust, day in and day out, reflecting a deep understanding of what industrial professionals truly need.

Ensuring Safety and Consistency on the Job

You know, in any industrial setting, safety isn't just a good idea; it's absolutely crucial. And consistency in performance, well, that's what keeps operations running smoothly and predictably. When you're dealing with powerful tools and demanding tasks, having products that you can trust to be both safe and reliable makes all the difference. It’s about creating an environment where people can focus on their work without constantly worrying about their equipment, which is very important for peace of mind.

Walter Surface Technologies puts a strong emphasis on these two aspects. They want you to choose Walter for the safest and most consistent performance on the job, which, in fact, speaks volumes about their product development philosophy. They understand that every tool used in a shop needs to meet high standards for both user protection and reliable output. This commitment helps ensure that workers can perform their tasks with confidence, knowing their tools are designed to keep them out of harm's way while delivering predictable results.

Prioritizing the Well-being of the Walter Clayton Jr Daughter Workforce

When we consider the "Walter Clayton Jr daughter workforce," we're thinking about the people who are actually on the shop floor, using these tools every day. Prioritizing their well-being means going the extra mile to make sure that the products they use are as safe as possible. It’s about designing tools that minimize risks, reduce fatigue, and contribute to a healthier work environment overall. This focus on human safety, you know, is a sign of a truly responsible company, one that values its users above all else.

The commitment to safety from Walter Surface Technologies is built into their products, ensuring that users can operate with a higher degree of confidence. This isn't just about meeting regulations; it's about a genuine desire to protect the people who rely on their tools. And consistency, too, plays a part in safety; predictable tools are safer tools. This dual focus means that the "Walter Clayton Jr daughter workforce" can expect equipment that not only performs reliably but also keeps them secure while they do their important work.

Why is Tool Identification a Big Deal in the Shop?

You might wonder why something as simple as tool identification matters so much in a busy shop environment. Well, imagine a place where dozens of different tools are used for various tasks, and each one needs to be picked quickly and accurately. If tools aren't easy to tell apart, you know, it can lead to confusion, wasted time, and even using the wrong tool for the job, which can be dangerous or just inefficient. It’s actually a pretty common problem in many workplaces, as a matter of fact.

This is where smart design choices, like color coding, come into play. Walter Surface Technologies, apparently, understands this challenge very well. They make their products color coded for easy identification in the shop. This simple feature helps workers quickly grab the right tool, whether they need to remove paint, rust, or corrosion, or perform lighter tasks. It speeds up the workflow, reduces errors, and makes the whole operation run a lot smoother, which, you know, is a significant advantage in a fast-paced setting.

Streamlining Operations for the Walter Clayton Jr Daughter Era

For the "Walter Clayton Jr daughter era," where efficiency and precision are paramount, streamlining operations is absolutely key. Easy tool identification is one of those small details that collectively make a huge difference in how smoothly a shop runs. It’s about reducing friction in the workflow, allowing people to spend more time on the actual work and less time searching for or verifying tools. This kind of thoughtful design helps to create a more productive and less frustrating work environment, which is very beneficial.

The color-coded system, for instance, helps to simplify the daily tasks for workers, ensuring that they can quickly find the right abrasive or tool for the specific job at hand. This practical approach to user experience is a reflection of a company that truly understands the needs of its customers, helping them to work smarter, not just harder. It’s a subtle but important way that Walter Surface Technologies supports the operational flow, making sure that every minute counts in the shop.

A Closer Look at Annular Cutters

When it comes to specialized cutting tasks in metalworking, annular cutters are a pretty important piece of equipment. They are designed to create clean, precise holes, often much faster and with less effort than traditional drill bits. Understanding the variety and capabilities of these cutters is key for anyone involved in heavy-duty fabrication or construction. It's not just about making a hole; it's about making the right kind of hole, with accuracy and speed, which is quite a specific requirement.

Walter Surface Technologies offers a complete range of these high-performance cutters. They have options in high speed steel, cobalt, and carbide tipped materials, which means they can handle different types of metals and cutting challenges. These are available in both the Walter and Drillco product programs, providing a wide selection for various applications. They even come in sizes up to 4 inches in diameter and 4 inches in depth, which, you know, covers a pretty substantial range of hole-making needs for industrial projects.

Precision Cutting with the Walter Clayton Jr Daughter Standard

If we think about a "Walter Clayton Jr daughter standard" for precision cutting, it would imply a commitment to the highest levels of accuracy and performance in every cut. It suggests that the annular cutters are designed not just to make holes, but to create them with exceptional cleanliness and exactness, ensuring that the finished product meets the most demanding specifications. This kind of standard would prioritize the quality of the cut, minimizing rework and maximizing efficiency, which is very important for industrial users.

The variety of materials available for their annular cutters – high speed steel, cobalt, and carbide tipped – means that users can select the perfect tool for the specific material they are working with, ensuring optimal precision. This wide offering, coupled with the range of sizes, allows for truly tailored cutting solutions, reflecting a deep understanding of the diverse needs within the metalworking industry. It’s about providing the right tool for every precise job, embodying a commitment to consistent

- Shannon Sharpe Standing Meme

- Tribal Braids With Sew In The Back

- Did Samantha From My Strange Addiction Get Skin Cancer

- Viral Cortisol Coffee

- Alexandra Saint Mleux Father

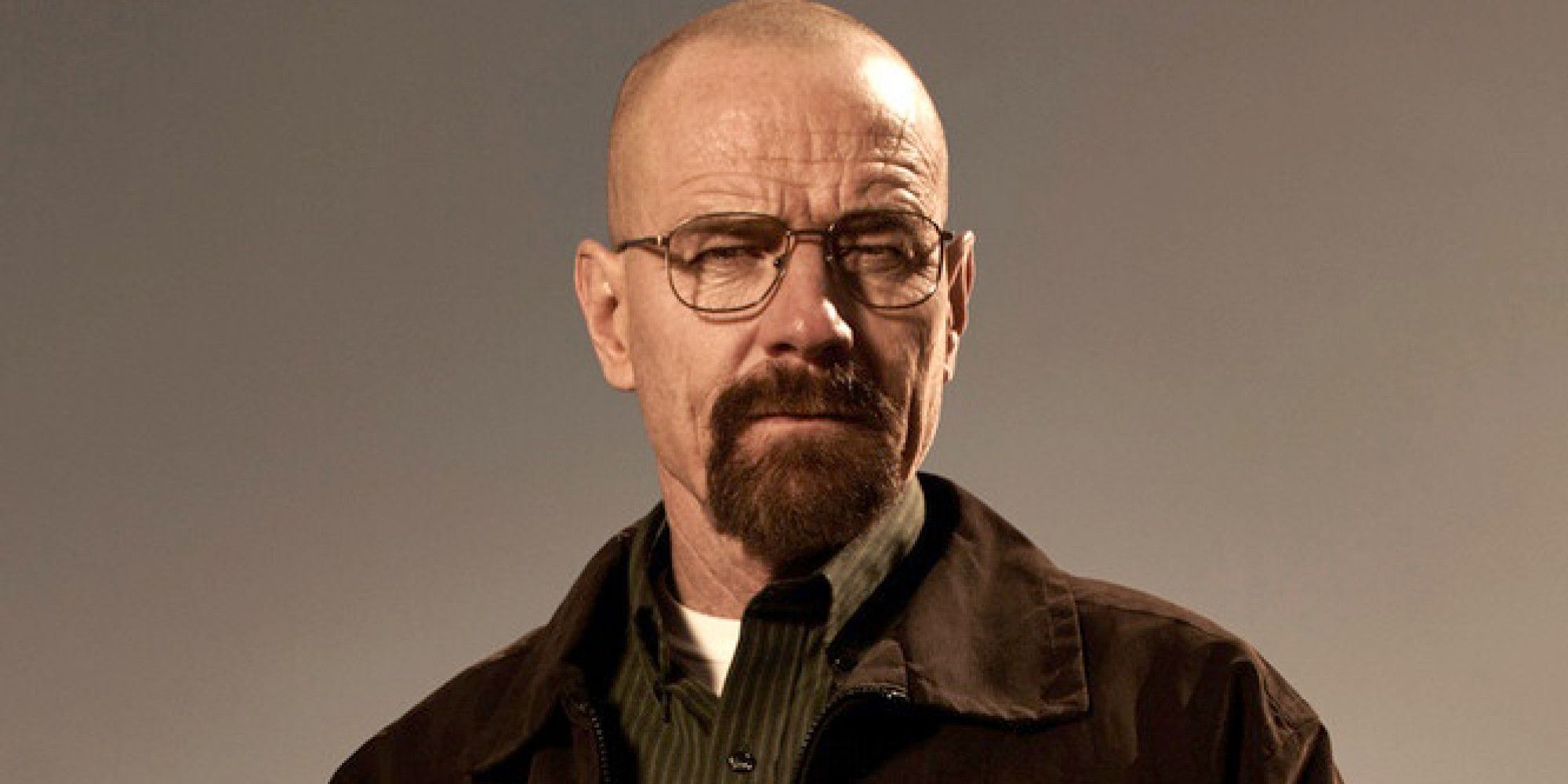

Wallpaper : Walter White, Breaking Bad, hat, men, Bryan Cranston

Artwork & Images | WALTER the Movie

Breaking Bad: 10 Characters Who Contributed The Most To Walter's Downfall